Packaging Equipment Sales has a full line of Blister Packaging Equipment, Blister Sealers and Clamshell Sealers. This Blister Packaging Equipment has extensive research and development behind each unit. We are the leading supplier of Blister Packaging Equipment. From table top blister sealers, right up to high speed conveyor blister sealers and clamshell sealers, we have the right blister packaging machinery for your application.

This video shows the basic principles of "How Blister Sealers Work". Any of the below steps can be done either by an operator or automatically depending on the machine configuration. A transparent thermoplastic form (Blister) is put into the tooling. Products are placed into the Blister. A Paperboard card (with a heat activated coating) or foil is put on top of the packed product. Heat and Pressure are applied to the Card and Blister. The sealed packages are removed from the machine. The Blister Packages are now ready for shipment and display at the point of sale. The Size and Speed Requirement are what determines the machine type.

When you need a Blister Sealer contact

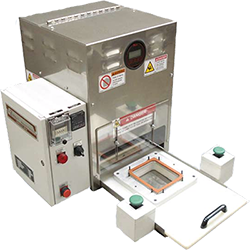

Bench Top Blister Sealers are small, portable, single-station blister packaging machines, "Bench Top Blister Sealers and Clamshell Sealers" designed for low to medium production of medical blister packs, pharmaceutical blister packs or general product blister packs and clamshells. These machines are excellent for startup companies. The table top blister sealers feature a low initial cost and are made with heavy duty components to withstand daily production of excellent quality blister packages for many years. Features include a compact/portable bench-top unit, energy efficient instant on/off heaters, timer controlled repeatability and all the latest safety features.

Two Station Blisters Sealers and Clamshell Sealers are an economical way to improve the output capabilities for small companies. These two operator blister packaging machines allow for product loading at two locations. While one operator is loading the machine the other operator is sealing. Two times the output speed at only a fraction more than the cost of a single station blister sealer. These blister sealers are mounted to a frame which could be equipped with casters to allow it to be moved when needed. Features include an economical price with more than two times the output of the Bench Top Model, ergonomic work height and large format work area. These blister sealers offer an exceptional value when considering all of the features and performance packed into these machines.

Rotary Blister Sealer and Clamshell Sealers are used for medium to higher volume blister packaging equipment applications and can be configured to allow for 8 station operation. The "rotary type" clamshell and blister sealers cycle times are dependent upon operator loading speeds and they can achieve approximately 10 to 20 cycles per minute and possibly more for an 8 station sealer. The rotary sealers are controlled by a PLC and settings for load time, seal time, temperature are adjusted by an included HMI for easy operator use. The "rotary" Clamshell and Blister Sealers are available with a long list of options that provide for customization to match all but the highest speed blister packaging and clamshell production criteria. Features include quick-change seal tools, PLC with machine functions controlled and adjusted via a touch screen operator interface, optional card and blister feeders available.

High Speed Automatic Blister Sealer and Clamshell Sealer machines are conveyor type blister packaging equipment designed specifically for high volume packaging applications. Theses top of the line high speed inline automatic blister sealers and clamshell sealers feature a servo chain driven system, precision four-post heat seal press (with precision ground platens and long bushings to ensure parallelism), a touch screen operator interface panel (for fast set-up and adjustment of operating parameters and sequences to the PLC) and is also available in different lengths (for optional automatic feeders and/or additional product loaders). An optional electronic impulse sealing system is available for clamshell sealing and two-piece blister sealing applications with numerous options are available to custom tailor a system to meet almost any application.

Here are links to the Clamshell and Blister Sealers mentioned above:

| Bench Top Sealer | Shuttle Sealer |

| Rotary Sealer | Automatic Sealer |

If your project requires entry level Packaging Machinery or the latest "top of the line" Packaging Equipment then we have some of the best high quality North American Made machines available. This website has only some of our machines listed and we have much more! Anytime you are producing Clamshell or Blister Packages and need Blister Packaging Equipment, we have the machines for your application, contact

We look forward to working with you on your project and being your packaging machinery supplier for many years to come.