Plastic Bottle Air Conveyor for conveying empty bottles including; PET bottles for soft drinks, distilled spirits, sports drinks, water bottles, ketchup, salad dressing, peanut butter. HDPE bottles for milk, water, juice and yogurt. LDPE squeezable plastic bottles. PP bottles for ketchup and bottled yogurt. If it is in a plastic bottle, we have the air conveyor for it.

Plastic Bottle Air Conveyors are used for empty bottle conveying after a blow molder, depalletizer or unscrambler when possible because they have a much faster response time when closing gaps in production to a filler, they also have simplified controls, less moving parts and are less expensive to operate and maintain than Vacuum or Table Top Conveyors. Once the bottle is filled then we can provide custom Table Top Conveyor or Mat Top Conveyor to meet your requirements. We have a large installed base of conveyors throughout the Pharmaceutical, Food and Beverage Industry.

Plastic Bottle Air Conveyors are used for empty bottle conveying after a blow molder, depalletizer or unscrambler when possible because they have a much faster response time when closing gaps in production to a filler, they also have simplified controls, less moving parts and are less expensive to operate and maintain than Vacuum or Table Top Conveyors. Once the bottle is filled then we can provide custom Table Top Conveyor or Mat Top Conveyor to meet your requirements. We have a large installed base of conveyors throughout the Pharmaceutical, Food and Beverage Industry.

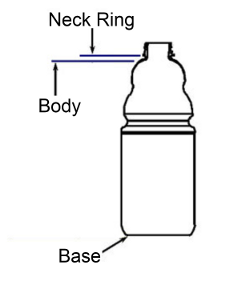

What is Plastic Bottle Air Conveyor? air conveyor has been around since the mid 80's, and was initially developed to move empty steel beverage cans, empty PET two piece bottles, and injection molded base cups. Now air conveyors are primarily used to convey bottle caps and blow molded empty plastic bottles. The style used to convey caps and other items with a lightweight and low center of gravity is called flat top air conveyor. The type of air conveyor in which we specialize, transport empty plastic bottles and are called Neck Ring (NR) Air Conveyor because it conveys empty plastic bottles by the neck of the bottle instead of by the base of the bottle.

How Neck Ring (NR) Plastic Bottle Air Conveyors Work: low pressure high volume air is directed into a louvered plenum. The louvers of the air conveyor are directional and allow the air to escape in the direction of the louver. A typical NR plastic bottle air conveyor is a three sided plenum, each side having a flat surface and fabricated in one piece using custom break presses. The fourth side or bottom of the plastic bottle air conveyor is separately fabricated and is referred to as the "Hat Section". This is because it takes the shape of a hat when viewed edge on. The Hat Section is the portion of the plenum that has the directional louvers. The louvers may be on one or two sides, depending on the engineering philosophy of the particular manufacturer. We use 2 sides for maximum speed and efficiency. The Hat Section of the NR plastic bottle air conveyor is riveted to the three sided plenum, using silicon as a gasket material along the full length of the pop riveted seam.

How Neck Ring (NR) Plastic Bottle Air Conveyors Work: low pressure high volume air is directed into a louvered plenum. The louvers of the air conveyor are directional and allow the air to escape in the direction of the louver. A typical NR plastic bottle air conveyor is a three sided plenum, each side having a flat surface and fabricated in one piece using custom break presses. The fourth side or bottom of the plastic bottle air conveyor is separately fabricated and is referred to as the "Hat Section". This is because it takes the shape of a hat when viewed edge on. The Hat Section is the portion of the plenum that has the directional louvers. The louvers may be on one or two sides, depending on the engineering philosophy of the particular manufacturer. We use 2 sides for maximum speed and efficiency. The Hat Section of the NR plastic bottle air conveyor is riveted to the three sided plenum, using silicon as a gasket material along the full length of the pop riveted seam.

The Hat Section is the area where the neck finish or neck ring (NR) of a container resides while being conveyed. On the underside of the hat section, a continuous neck rail support or strip of metal about two inches wide is bolted to each side of the hat opening. These supports are adjustable in and out. It is on these supports that the conveying surface is attached. The conveying surface is usually a specially formulated extruded plastic wear strip that snaps in place via a continuous groove that is extruded into the profile. This material has an extremely low CF (Coefficient of Friction) with PET (Polyethylene terephthalate). As a bottles' neck ring is introduced into the plenum, the high volume low pressure is forced through the directional plenums in the Hat Section. As the air escapes it moves over and to each side of the bottles neck finish, causing lift due to its interaction with the neck ring, much like air moving over and under a aircraft wing. This lifts the bottles and propels it forward at high speed. Because the air is low pressure, very little back pressure is exerted over distances of up to 300 feet compared to standard table top chains. Air is supplied to the plenum by external fan/motors every 50-60 feet.

The Hat Section is the area where the neck finish or neck ring (NR) of a container resides while being conveyed. On the underside of the hat section, a continuous neck rail support or strip of metal about two inches wide is bolted to each side of the hat opening. These supports are adjustable in and out. It is on these supports that the conveying surface is attached. The conveying surface is usually a specially formulated extruded plastic wear strip that snaps in place via a continuous groove that is extruded into the profile. This material has an extremely low CF (Coefficient of Friction) with PET (Polyethylene terephthalate). As a bottles' neck ring is introduced into the plenum, the high volume low pressure is forced through the directional plenums in the Hat Section. As the air escapes it moves over and to each side of the bottles neck finish, causing lift due to its interaction with the neck ring, much like air moving over and under a aircraft wing. This lifts the bottles and propels it forward at high speed. Because the air is low pressure, very little back pressure is exerted over distances of up to 300 feet compared to standard table top chains. Air is supplied to the plenum by external fan/motors every 50-60 feet.

For very competitive pricing on "New" Air Conveyor (50 feet in length or greater), contact us

How Plastic Bottle Air Conveyors Improve Bottling Efficiencies: Plastic Bottle air conveyor motors are super energy efficient and run continually, there is no start and stop of the motor system. They are is passive escape system when the line is in a back-up condition. So running or not, the same energy is expended because the product is floating and not in frictional contact with a surface like table top chain. Efficiencies are always improved because there is very little queue and recovery is almost instantaneous compared to table top chain. Since bottles are confined by their neck ring in the hat section, and the main diameter of the bottles is guided on both sides, bottles do not fall and produce jam points. Air conveyors allow fillers to run at their optimum speeds.

How Plastic Bottle Air Conveyors Reduce Cost :

How Plastic Bottle Air Conveyors Reduce Cost :

When using table top conveyor the costs are:

For information on other types of Conveyors use this link:

More Conveyors

Why you should contact Packaging Equipment Sales for your next conveyor project: We have the right type of conveyor for your application. We know what information is needed to properly select the correct technology and what features you will need to meet your requirements. We can give budgetary numbers for your project almost instantaneously. If you need a formal proposal, you will not get it any faster than we will be able to provide it.

One call to Packaging Equipment Sales will save you time and money, contact us